Finding cost-effective, sustainable energy is more than just a buzzword, and CHP may deliver the answer. Combined heat and power systems use a single fuel source to provide heat and electricity for a building, typically facilities with a consistent, ongoing thermal load.

CHP Systems:

- Have 70%-80% efficient systems compared to 50% for standard systems

- Meet sustainability goals

- Provide reliable onsite energy generation

- Reduce emissions and energy costs

What is CHP or Cogeneration?

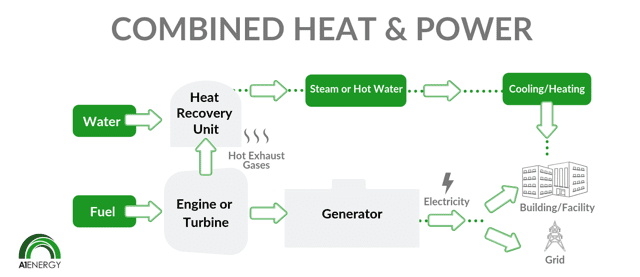

Cogeneration systems reclaim excess heat from electric power generation. The most common fuel source is natural gas, although diesel, coal, and biomass may be used, too. Some systems can harvest geothermal or nuclear power. The systems are designed to capture the byproduct heat, usually steam, and use it within the host site's facility.

Additionally, newer CHP systems provide power back-ups in the event of an outage, ever more critical as the grid becomes more unreliable.

Cost-Effectiveness of CHP Systems

As businesses and governments seek energy efficient technology, and with the current price of oil burgeoning, finding energy sources that are both cheaper and more sustainable can help emerging markets grow. In fact, the Department of Energy conducted a study that identified several market conditions currently contributing to CHP growth:

- Lower energy operating costs

- Resiliency initiatives

- CHP-friendly market regulations

- Utility support

- Federal and state policies and incentives

- Project replaceability

Plus, as we mentioned above, cogeneration power systems reduce the strain on the electric power grid. One needs only to look at the state of the Texas power grid during an unexpected snowstorm in February of 2020 to see how easily a power grid can be overwhelmed. Opting for CHP systems instead of separate heating and electrical systems can ease that burden nationwide.

CHP systems have lower greenhouse gas and other harmful emissions and may be a viable option for developing new transmission and distribution infrastructure for clean energy.

DOE Analysis of CHP Systems

CHP technologies involve either a "topping cycle" or "bottoming cycle." Topping cycles, the most common use, burn fuel to create electricity. Part of the generated heat converts to thermal energy, which is then used for heating water, space heating, or industrial process steam.

The bottoming cycle is more common in large-scale industrial applications and uses fuel for industrial processes, such as in a furnace or kiln, and captures the waste from the heat for power production.

Eliminating the wasted heat and instead redirecting it into efficient usage drops operating costs for businesses and results in a more sustainable production cycle. Some other points to consider from the DOE report:

- "Across all CHP categories, there is estimated to be more than 240 GW of technical potential at over 291,000 sites within the U.S."

- "In contrast to the existing facilities with installed CHP, which are heavily concentrated at large industrial and manufacturing facilities, a significant portion of the remaining technical potential for on-site CHP in the U.S. is located in commercial facilities."

The Rise of Modern CHP

Using waste heat for power generation isn't a new trick. In 1882, Thomas Edison produced both electricity and excess steam to heat buildings close to his Pearl Street Station. At the turn of the 20th century, early electricity providers sold steam to local customers for industrial use or heating homes. Because steam can't be transported over long distances, this early CHP was limited to immediate local areas.

As the 20th century progressed, some manufacturing sectors used bottom-cycle CHP to turn exhaust into electricity, such as chemical plants, food processors, and paper mills. However, CHP remained largely underutilized until the Arab oil embargo in the 1970s. The electrical conservation plan of President Carter led to a shift in power generation, and non-utility generators (NUGs) rapidly emerged. The new CHP technologies changed how electricity could be sold and resulted in large-scale cogeneration.

Talk With Our CHP Team

Our CHP Team will conduct a review of your facility to see if CHP is right for you. Work with a trusted partner on your CHP project.

The Future of CHP

The Department of Energy has a long-standing goal of having a 20% generating capacity in the U.S. from CHP sources. Partnerships between the DOE and CHP "promote and assist in transforming the market for CHP, waste heat to power, and district energy technologies/concepts throughout the United States."

Microgrids, especially benefit from CHP, which can solve reliability and cost issues. Additional efficiency, environmental, and cost benefits from combining power creation with heating and cooling make CHP systems increasingly desirable.

Takeaway - New Opportunities for CHP

CHP systems are developing rapidly throughout the world, including emerging nations. Russia is the most aggressive developer, with the EU close behind. India, on the cusp of rapid development, is another ripe candidate for CHP, leveraging the sugar industry byproducts for energy. Stateside, developers and local municipalities can benefit from CHP systems and microgrids, preserving the integrity of the grid and reducing heating and cooling costs even as electrical demands increase.